- Home

-

About us

About us

- News

News- Products

Products- Project

Project- Investor

Investor- Contact

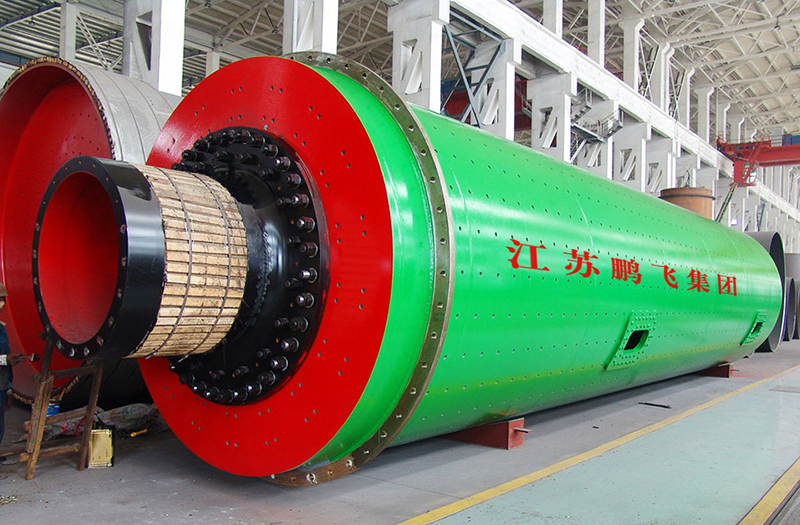

Ball milling

Air-Swept Coal Mill-

-

Description: The wind swept coal mill is used for drying and grinding coal powder. It mainly consists of a feeding device, main bearings, rotating parts, transmission device, rolling device, high-pressure starting device, and lubrication system. The raw materials are loaded into the mill through the feeding equipment, and hot air enters the mill through the inlet duct. As the mill cylinder rotates, coal and hot air exchange heat in the mill, and coal is crushed and ground in the mill. At the same time as coal is ground, fine powder is carried out of the mill through the discharge device by the hot air inside the mill. The wind swept coal mill has a reasonable structure and high grinding efficiency, making it an ideal equipment for coal powder preparation....

+86-513-88755311 88755027

The wind swept coal mill is used for drying and grinding coal powder. It mainly consists of a feeding device, main bearings, rotating parts, transmission device, rolling device, high-pressure starting device, and lubrication system. The raw materials are loaded into the mill through the feeding equipment, and hot air enters the mill through the inlet duct. As the mill cylinder rotates, coal and hot air exchange heat in the mill, and coal is crushed and ground in the mill. At the same time as coal is ground, fine powder is carried out of the mill through the discharge device by the hot air inside the mill. The wind swept coal mill has a reasonable structure and high grinding efficiency, making it an ideal equipment for coal powder preparation.

Characteristics of Grinding Machine

1. Reliable operation, continuous operation, and high production capacity. 2. Less transmission components and lower maintenance costs. This is a design that highlights the advantages and disadvantages of the open flow grinding system, and makes significant improvements to the traditional ball mill. In addition to all the advantages of open flow grinding, compared with ball mills of the same specifications, the output of the mill has been greatly improved, and the powder is fine and the specific surface area has increased, achieving high yield and high fineness, providing a new type of grinding equipment for the production of high-grade cement.

Technical

Specifications(m)

(Diameter×Length)Rotational speed

(r/min)Feed particle size

(mm)Production capacity

(t/h)Grinding body loading capacity

(t)Main motor

ModelMain motor

Power(kw)Main motor

Rotational speed(r.p.m)Main reducer

ModelMain reducer

Speed ratioWeight(t)

Excluding motor reducerΦ2.2×4.4 22.4 ≤25 8-9 18 YRKK4501-6 250 986 ZD60-11 6.3 36.7 Φ2.2×5.8 22.4 ≤25 5.5-7 23.5-25 Y4005-8 280 750 ZD70-10 5.6 45 Φ2.4×4.75 21.2 ≤25 9-11 22-24 YR4501-8 315 740 ZD60-8 4.5 49 Φ2.4×(6+1.5) 20.2 ≤25 14-16 31 JR158-8 380 740 ZD70 5 77.3 Φ2.4×(4.5+2) 20.2 ≤25 11-13 20.8 YRKK500-8 280 740 JDX45 4.5 68 Φ2.6×(5.25+2.25) 19.7 ≤25 12-14 28 YRKK500-8 400 740 ZDY450 4.5 87.4 Φ2.8×(5+3) 18.7 ≤25 16-18 32 Y5001-8 500 740 JDX560 4.5 102 Φ2.9×4.7 19.1 ≤25 14-19 34.4 YR560-8 500 743 MBY560 5.6 79 Φ2.5×3.9 21 ≤25 14 21 JR138-8 280 740 ZD70-9 5 49.5 Φ3×(6.5+2.5) 18.3 ≤25 17-19 43 YRKK560-8 630 740 MBY560 5 120 Φ3.2×(6.5+2) 16.9 ≤25 20 48 YRKK560-8 710 740 MBY560 5 118 Φ3.2×(6.5+2.5) 16.9 ≤25 20 50 YRKK560-8 710 740 JDX630 5 140 Φ3.4×(6+3) 17.47 ≤25 20-24 54 YRKK630-6 700 988 MBY710 7.1 135 Φ3.5×7 17 ≤20 22-25 70 YRKK630-6 100 970 JH630 9 170 Φ3.5×8 17.2 ≤25 55-60 80 YRKK710-8 1000 740 MBY800 6.3 182 Φ3.5×(8+3) 16.8 ≤25 27 58 YRKKK630-8 1000 740 JDX800 6.3 178 Φ3.5×(6.5+3.5) 16.8 ≤25 30 62 YRKK710-8 1250 740 JDX900 6.3 182 Φ3.6×(6+3) 17 ≤25 30-32 60 YRKK710-8 1000 740 MBY800 6.3 183 Φ3.8×(7.75+3.5) 16.7 ≤25 85 85 YRKK710-8 1400 740 JDX90 5.6 215 label:Air-Swept,Coal,Mill,Specificat- Previous: No more

- Next: Raw mill

Related products

Copyright © 2025 Jiangsu Pengfei Group Co.,Ltd. All Rights Reserved. - News